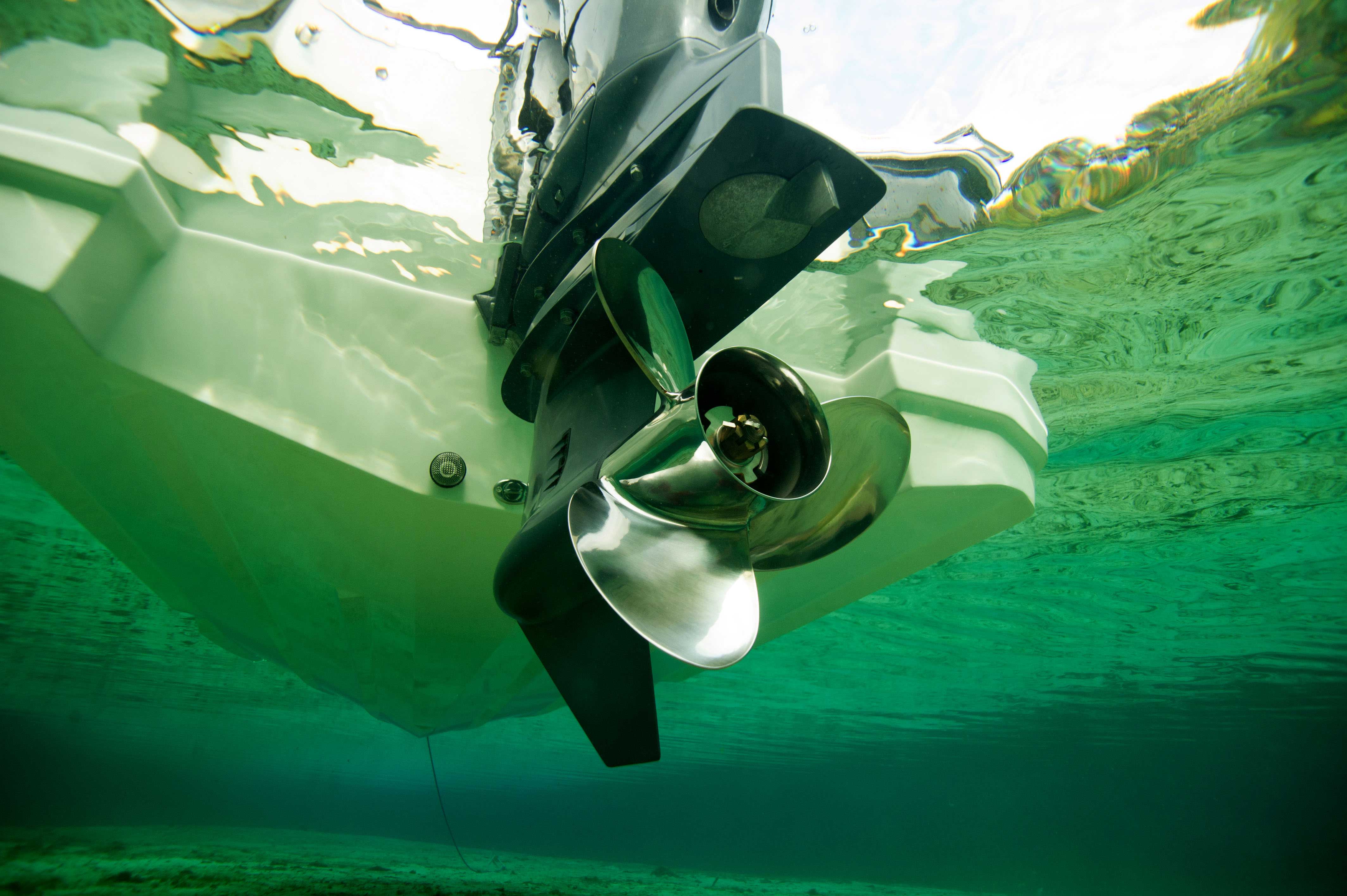

When it comes to boat propellers for outboard-powered vessels, owners have two main options: aluminum and stainless steel. While it's true, there are other niche choices, chances are you fall into the 99% of operators who would be served best by an aluminum or stainless steel propeller.

Frequently, misinformation about propeller materials is distributed online, down at the docks, and even in established boat shops and dealerships. However, both options have their own unique set of benefits and drawbacks. In the following article, I hope to bring clarity to the issue and build confidence in your decision.

The range of selection regarding size and design will typically be more significant in one material than the other based on the size of the motor. In general, aluminum props are the most common choice for engines 30-70hp, while stainless steel is usually selected for motors 75hp and up. That doesn't mean if you have a 50hp, a stainless steel prop isn't a good option for you, nor does it mean that if you have a 250hp, you are obligated to use a stainless steel prop. It means you will have more choices with one option than the other, depending on your motor.

Most small gas and electric outboards from 2.3hp - 25hp come with a factory prop, which will almost always be aluminum, although some very small motors may come with a composite. Stainless steel options for motors 25hp and under are few.

First, let's talk about expenses. Aluminum propellers are more affordable than their stainless steel counterparts. This, of course, will save you money on a relatively expensive part that does need occasional replacement. However, aluminum props will require periodic replacement and are less fuel efficient. This aspect should only affect your decision if you are already stretching your budget. All boaters should approach any decisions with consideration of safety and redundancy. An aluminum prop, plus an additional aluminum unit as a spare, could be a better option than a single stainless steel one or not having a spare at all. The cost is roughly the same, and depending on what type of water you are boating in, having a spare prop (especially a primary prop that is aluminum) is a must. For some, having a stainless primary and aluminum backup is a clear choice.

The next consideration is the complex subject of propeller weight. Aluminum props are significantly lighter, which historically has been a great thing for reducing wear and tear on the motor and lower gear set, mitigating gear shifting noise/vibration, and fuel efficiency. However, modern outboards, especially 75hp+ models, are built to handle the weight of a stainless prop. Recent hub innovations like Yamaha's SDS and Mercury's Flo-Torq SSR Hub Systems reduce the wear and tear from a heavy prop and dampen the shifting clunk for soft, quiet shifting. Additionally, modern designs of stainless props optimized for fuel efficiency take advantage of the lower deflection rates of stainless steel.

Durability is a huge factor when choosing the right prop. Boaters across the nation face a wide range of water conditions, from deep clear water, shallow brackish water, water full of debris, and sea beds of silt, clay, and rock. Aluminum propellers are more forgiving when it comes to striking underwater objects, meaning that they will dent, bend, and deform but being a softer metal, it doesn't take much of a strike to do so, and they are more easily damaged than their counterpart.

Stainless steel is far more durable and can handle much harder strikes without taking damage. However, in a situation where the impact is enough to damage the prop, the damage will often be much more catastrophic and can present as cracks, detached blades, split hubs, etc. If your waters are commonly high debris or rocky, breaking stainless props can get expensive quickly. Sometimes, minor damage to either material can be repaired, but a replacement of a damaged aluminum prop is usually recommended. Thanks to the high durability, the expected lifespan of a stainless steel prop in most applications is much longer than aluminum.

Befitting of its name and the hardness of the material, stainless steel will be more resistant to corrosion. Aluminum is a soft metal, and especially on boats that live in salt water, corrosion over time can be expected, much like a sacrificial anode. Proper maintenance and regular inspection are critical for both materials, but aluminum props should be closely monitored.

Now the moment everyone is waiting for… what about performance? This category has a clear winner, depending on your boat and motor combo. The significant surface area of a large prop and the high torque production of a large displacement motor will cause the softer aluminum metal to deflect under load. Loads causing deflection can be high RPMs, low RPM launching of heavy or non-full planing boats, watersports, and towing. Stainless steel will hold its shape (which for a prop means grip in the water and then thrust) much better than aluminum. Whether your priority is top speed, hole-shot, or all-around maximized performance, a stainless prop will be the way to go. For small motor planing hull applications, lighter aluminum will mean the motor can spin the prop up to speed much faster than a stainless prop resulting in less lag on take-off and faster hole shots. However, the high RPM deflection will still be an issue at the top end and shave off some top speed.

So, which is the better choice: aluminum or stainless steel? The answer ultimately depends on the specific needs of your boat, where you operate it, your desires for your boat's performance, and your budget. Align those parameters with the pros and cons we identified here, and your choice should be clear.

For more information or to purchase a propeller please call our parts department at 805-644-6290 x3 or email parts@boatspecialists.com.

About the Author. Casey Carmichael is the Repower and Outfitting Specialist at Boat Specialists in Ventura, CA. Casey has been boating his entire life and was sailing before he could walk. Casey’s grandfather and father were both accomplished sailors so it was only natural for him to eventually end up in the maritime industry himself. Since day one in the business, Casey's technical knowledge in a variety of areas from electronics to rigging, have made him an invaluable resource in the industry.